From lab experiments to factory floors—meet the electric-powered Atlas robot mastering complex tasks through AI, agility, and a touch of grit.

- A New Breed of Robot: Atlas swaps clunky hydraulics for nimble electric actuators, achieving unprecedented speed, strength, and precision while ditching the “oily mess” of its predecessor.

- AI-Powered Problem Solving: Trained on real-world data, Atlas now troubleshoots errors autonomously—like adjusting misaligned parts—ushering in a new era of adaptive robotics.

- Real-World Ready: Already tackling automotive manufacturing logistics, Atlas proves humanoids can handle intricate, repetitive workflows once deemed too complex for machines.

For decades, humanoid robots existed as sci-fi fantasies or lab curiosities—too fragile, too impractical, too human to justify their cost. But Boston Dynamics’ latest iteration of Atlas, revealed in their recent video “Pick, Carry, Place, Repeat,” shatters these limitations. Designed to navigate environments built for humans, Atlas isn’t just mimicking our movements—it’s redefining what robots can do.

Goodbye Hydraulics, Hello Electric Agility

The original hydraulic-powered Atlas stunned audiences with backflips and parkour, but its complexity made it a high-maintenance lab resident. The new Atlas, however, is leaner and meaner. By replacing hydraulics with custom electric actuators, Boston Dynamics created a robot that’s 20% faster, 50% stronger, and far cleaner. Engineers joke about their oil-free lab floors now—a small but symbolic victory for practicality.

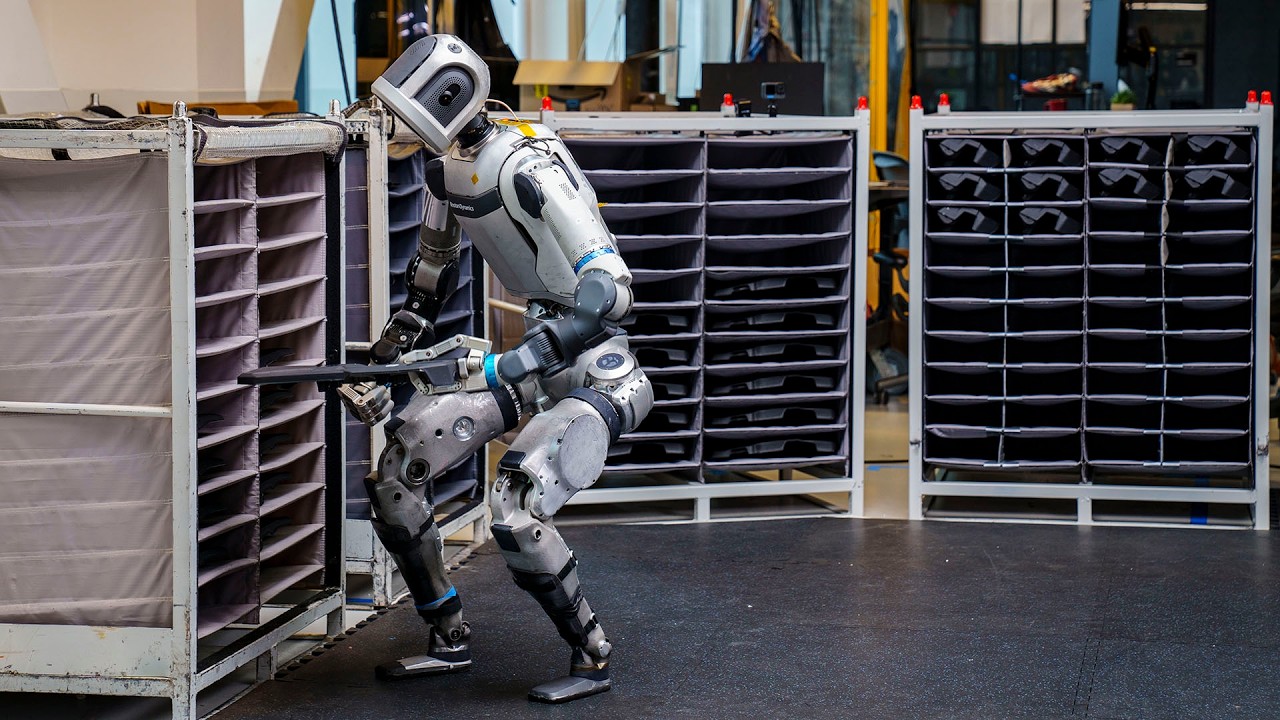

The secret? Rotating joints with 360-degree motion, letting Atlas twist its torso, crane its neck, or pivot mid-stride. This isn’t just flair; it’s functional. In a factory demo, Atlas uses this agility to duck under shelves, sidestep obstacles, and pivot to scan workstations—all while balancing a 25-pound engine cover.

Brain Over Brawn: How Atlas “Learns” to Manipulate the World

Humans instinctively know how to grip a coffee cup or nudge a misaligned drawer shut. For robots, these tasks require years of trial and error—or, in Atlas’ case, AI trained on petabytes of real-world data.

Boston Dynamics’ engineers feed Atlas simulations and footage from its own cameras to build a “mental model” of objects. When tasked with sequencing car parts, Atlas:

- Scans its environment via head-mounted cameras to locate engine covers.

- Adjusts grip strength based on an object’s weight and texture.

- Detects errors (e.g., a jammed part) and recalibrates—no human input needed.

“Atlas isn’t programmed for every scenario,” explains a roboticist in the video. “It generalizes—like a human apprentice learning to troubleshoot.”

From Lab to Assembly Line: Atlas Tackles Automotive Sequencing

The video’s standout demo? Atlas mastering automotive sequencing—a logistical nightmare where thousands of custom parts (e.g., engine covers) must be sorted into precise assembly orders.

Here’s how it works:

- Step 1: Atlas receives a digital map of the output dolly (goal) and input bins (parts).

- Step 2: Using cameras, it identifies the next required part, navigates clutter, and grabs it.

- Step 3: After placement, Atlas gives the part a final shove—a “confidence check” to ensure it’s seated correctly.

This isn’t theoretical. Boston Dynamics is already testing Atlas in partner factories, where a single robot could replace hours of manual sorting.

The Road Ahead: Why Humanoids Matter

Critics argue humanoids are overengineered—why build two-legged bots when wheels suffice? But Boston Dynamics counters: “The world is human-shaped.” Stairs, tools, and workspaces are designed for our bodies. Atlas’ value lies in plugging into existing infrastructure without costly retrofits.

The team’s 15+ years of bipedal research also pays off in unexpected ways. Atlas’ balance algorithms, refined through years of falls and flips, now let it crouch, lean, and recover from shoves mid-task—a lifesaver in chaotic factories.

More Than a Machine

Atlas isn’t just a robot; it’s a proving ground for a future where machines adapt to us. With AI-driven problem-solving, athletic agility, and a work ethic that never tires, Atlas hints at a world where humanoids handle dangerous, repetitive jobs—freeing humans for creative roles. As one engineer quipped: “We didn’t build Atlas to replace people. We built it to go where people can’t.”